Booster Pump Design

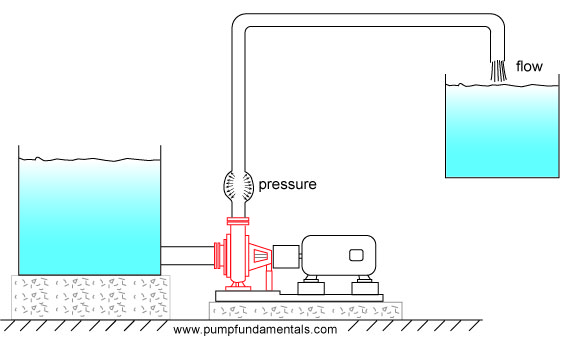

Booster pump design. Booster pumps are placed before the main pump. Depending upon the application at hand cold or hot water boosting pumps are available. Booster pump design on sale manufacturers find details about booster pump design manufacturers supplier and wholesaler - Guangdong Ruirong Pump Industry CoLtd.

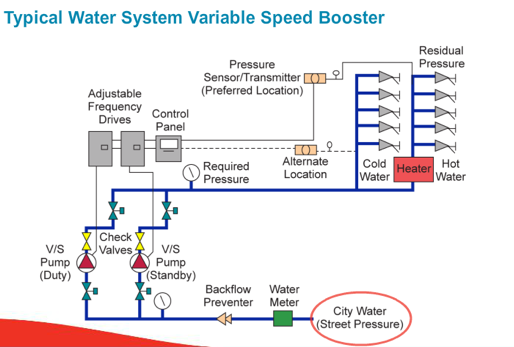

But before we search for a booster system that can deliver a design flow 240 gpm at 239 feet head there are additional factors that influence pump selection. There will be three pumps 1 1900 gpm 150 hp pump and 2 Duty pumps 45 gpm 2hp. Domestic water booster pumps are auxiliary pumps which are used to increase or maintain pressure in a potable water system.

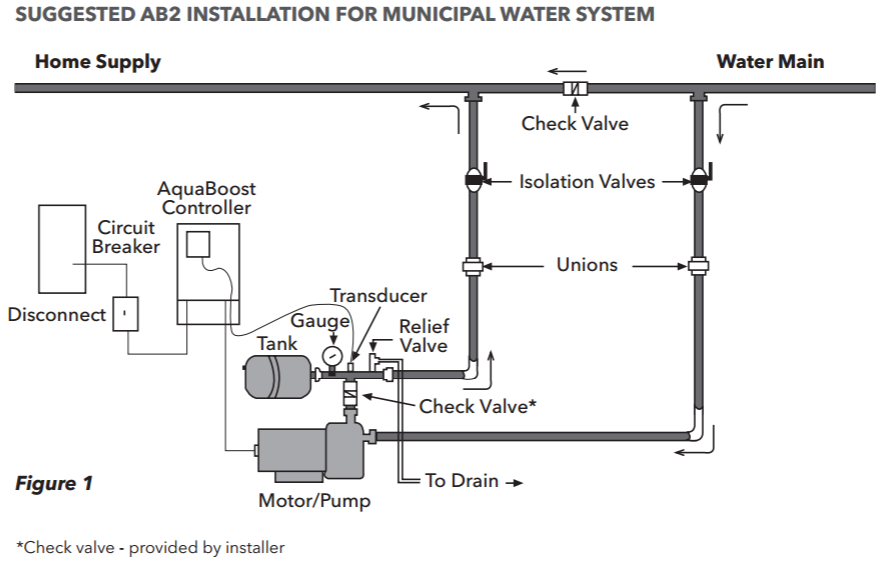

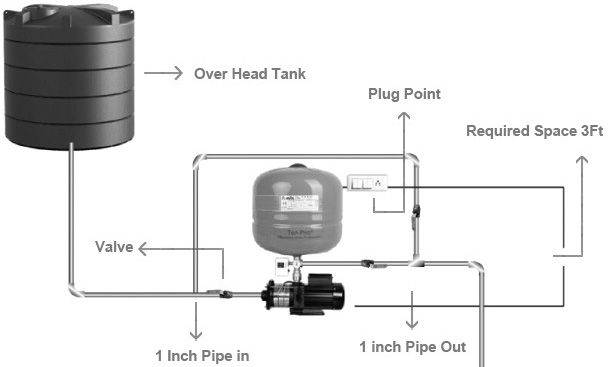

The pump station will be pumping from a storage tank to a higher pressure zone system. PROPOSED APARTMENT COMPLEX FOR MSCLEARPOINT RESIDENCIES PVT LTD. I am specifying my first water booster pump and would like to hear how you other engineers determine whether a booster pump is needed and the amount of pressure boost that is needed.

A convenient guide for Domestic Booster Pump Design. A real-world scientific solution for redundancy problems can be formulated without the need to add another pump or arbitrarily double the flow capacity. There are many others so do not hesitate to contact our team at boosterspumpsukltdcouk for advice on your next pump.

Normally double-entry vertically split pumps are employed for. They provide the necessary suction head for the feed pumps so that this does not cavitate within its specified operating range. Request a free quote.

T1 t2 t2 pe pt-2 2 1 pt-1 booster pump no2 booster p1 pump no1 p2 2 1 61 68 69 61 68 69 t1 t2 t2 pe pe pe 6800 ivs series plc c1 no1 no2 no3 j12 g0 id1 id2 id3 j5 id4 id5 id6 j2 g b1 24vdc b2 idc1 j10 y1 y2 y3 vgo field gnd - card no7 c7 j1 j14 vg c8 no8 gnd - 1. Industrial pressure booster water pumps are usually characterised by high pressure rather than high flow capabilities which sees multistage centrifugal and side channel pumps being ideal solutions. For optimal pump consistency and efficiency you should create a flow profile for your building tracking pump demands and the high usage point throughout your pumps daily cycle.

When the demand is low the booster pump is on standby. Undersized pipes common in poor plumbing design which produces same results as a clogged pipe.

This page is part of the Pump Tutorial Series.

But before we search for a booster system that can deliver a design flow 240 gpm at 239 feet head there are additional factors that influence pump selection. A water pressure boosting pump essentially refers to any. Typically booster pumps are used in water systems or applications that have low waste contamination. Ebara CDA400200T 3kW 380V Booster System - 190 lmin max. Calculations Booster pump sizing. For small installations single-stage overhung pumps designed for the high feedwater temperatures are used. Variable speed booster systems. Industrial pressure booster water pumps are usually characterised by high pressure rather than high flow capabilities which sees multistage centrifugal and side channel pumps being ideal solutions. All booster pumps and booster systems take advantage of the additive pressure rule that applies to series pump operation regardless of whether their source is another pump a municipal water line or and elevated tank.

45 Bar min pressure 68 Bar max pressure. Ebara CDA400200T 3kW 380V Booster System - 190 lmin max. Undersized pipes common in poor plumbing design which produces same results as a clogged pipe. Life with low water pressure is a nuisance. 45 Bar min pressure 68 Bar max pressure. 21 Londonderry Turnpike Hooksett NH 03106. Typically booster pumps are used in water systems or applications that have low waste contamination.

Post a Comment for "Booster Pump Design"